Blog

Maintenance of your boat trailer brakes

[fusion_builder_container hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” hundred_percent_height_center_content=”yes” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” publish_date=”” class=”” id=”” link_color=”” link_hover_color=”” border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ gradient_type=”linear” radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ background_blend_mode=”none” video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ type=”legacy”][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ gradient_type=”linear” radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”true” border_sizes_top=”0″ border_sizes_bottom=”0″ border_sizes_left=”0″ border_sizes_right=”0″ first=”true” type=”1_1″][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” content_alignment_medium=”” content_alignment_small=”” content_alignment=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” sticky_display=”normal,sticky” class=”” id=”” font_size=”” fusion_font_family_text_font=”” fusion_font_variant_text_font=”” line_height=”” letter_spacing=”” text_color=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=””]

[fusion_dropcap color=”” boxed=”yes” boxed_radius=”0px” class=”” id=””]M[/fusion_dropcap]ost states require brakes to be installed on trailers with a gross weight of 3,000 pounds or more.

Disc brakes offer more stopping power.

Your boat trailer brakes can be actuated with a surge actuator or with an electric over hydraulic brake system.

For the surge actuator, a master cylinder is located inside the trailers coupling device. When the tow vehicle brakes, the inertia of the decelerating trailer drives a piston into the master cylinder, which increases hydraulic fluid pressure along the brake lines to the calipers on the tires, hence, stopping the trailer.

For the electric over hydraulic system, once the driver presses the tow vehicles brakes, the brake pump sends the hydraulic fluid pressure along the brake lines to the calipers on the tires and stops the trailer. For this system, you need to make sure that your truck is equipped with a brake controller in the cab.

Disc brakes consist of a rotor oriented on the wheel axle. During braking, a piston actuates calipers that press against the rotor, creating friction to stop the wheel.

Disc brakes tend to have greater stopping power and greater resistance to fade and perform better in wet conditions. They are also self-adjusting and easier to inspect and maintain.

That said, their rotors are usually made of steel, which is prone to corrosion. Rinse metal parts thoroughly with fresh water after each launch.

Brake pads are a routine wear item. Follow the manufacturer’s instructions for indications of when it is time for replacement. Brake lines are another regular service item. Fluid levels should match the manufacturer’s recommendations. If brake lines need to be replaced or bled, carefully follow the manufacturer’s instructions.

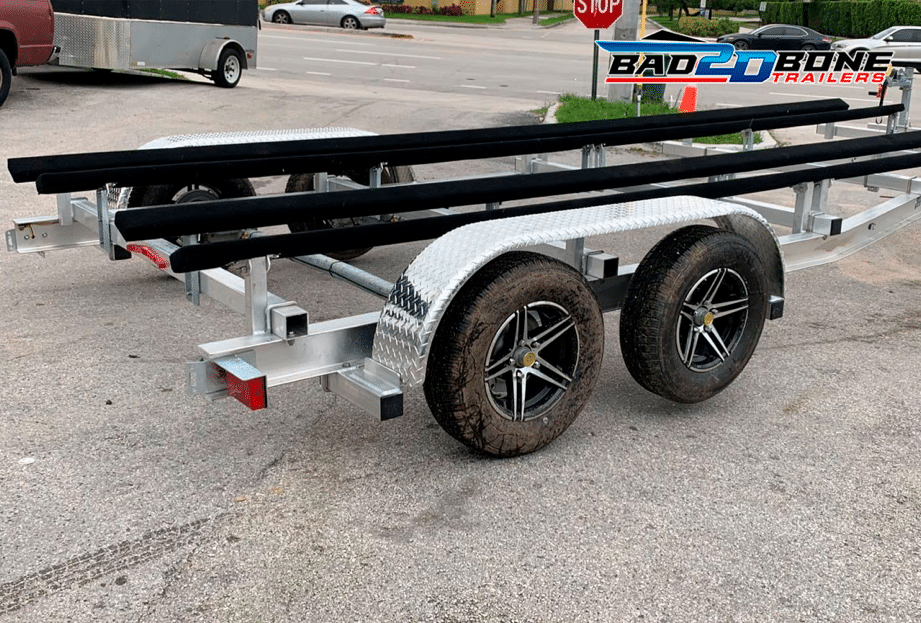

At BAD 2D BONE TRAILERS, we manufacture aluminum boat trailers and service your boat trailer.

We are at your service.

Contact us

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]